Hydraulic Breaker Chisel Excavator Blunt Wedge Diamond Point

Chisel Description

For preferred raw material suppliers, 40Cr and 42CrMo materials are considered to be high-quality choices. Both materials have good mechanical properties and durability and are suitable for some applications that require high strength and high wear resistance. In terms of heat treatment, specially improved heat treatment equipment can use advanced processes and equipment to ensure the quality and performance of materials. Through five heat treatment processes, including two staged tempering, the depth of the hardened layer can be effectively increased and the hardness and durability of the material can be improved. In this way, the service life of the product can be increased by 30% to 80%. These improvements can make 40Cr and 42CrMo materials more durable and stable. When selecting raw material suppliers, ensure that materials are of high quality and meet standards, while improved heat treatment processes can further enhance material performance.

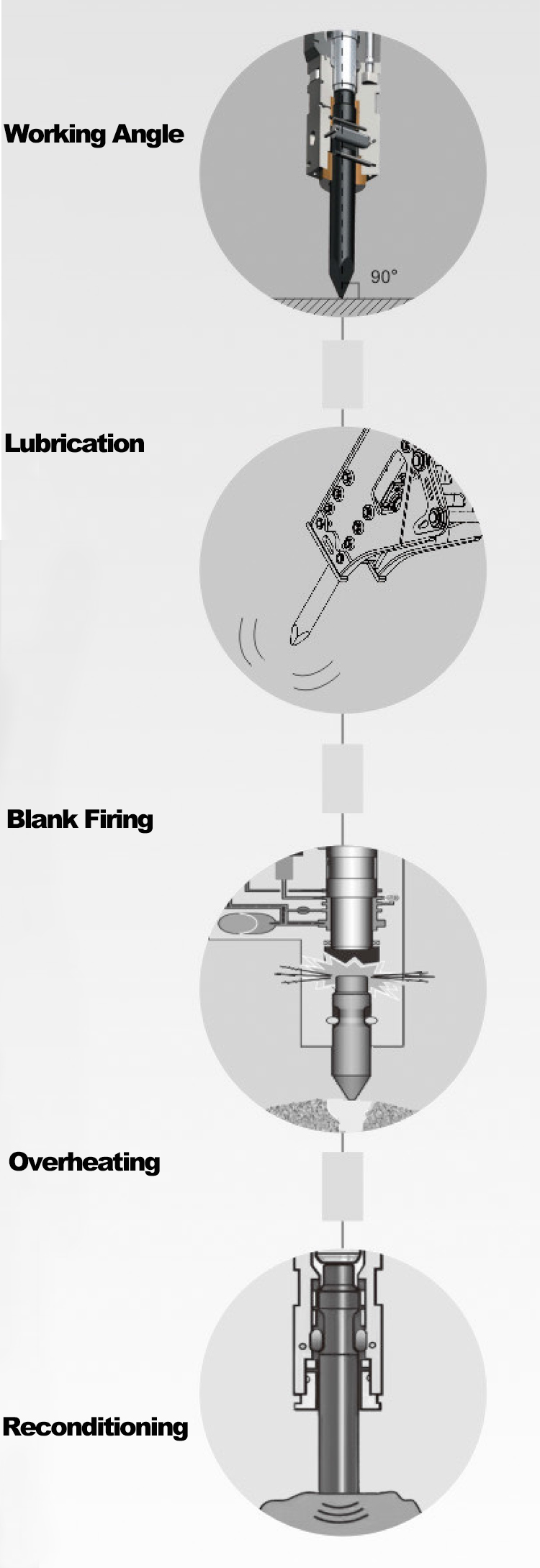

Working Angle

vertical strike operation It is correct to make the rod and the working surface perpendicular to an angle of 90°, so as to ensure the service life of the rod. If the angle is incorrect, higher pressures will develop between the rod and bushing, causing wear on the contact surfaces and potential damage to the rod or bushing. Worn bushings can cause rod tilt and subsequent damage to the piston.

Lubrication

lubricating Regularly use high-quality high-temperature and high-pressure lubricating oil to lubricate the contact surface between the rod and the bushing. Incorrect working methods, such as striking at an angle, prying the object or bending excessively, can produce high stresses on the contact surfaces. Lubricants provide better protection and extend service life.

Blank Firing

Dry hit Dry strikes can occur when the rod does not fully contact the work surface, slips on a broken object, or the object is too soft or thin. The rod may strike the retaining pin, and the force of the impact may cause severe wear or breakage of the pin. It is recommended to inspect the pole regularly, preferably every 30-50 hours, to check for damage and repair any defects. Also, check the bushings for wear or damage and replace or repair as necessary.

Overheating

The temperature is too high and mushroom phenomenon appears Avoid hitting one position continuously for more than 10-15 seconds. Hitting for a long time without breaking the object will prevent the heat from dissipating inside the club head. When too much heat builds up, the sticks can decarb and become soft, causing mushrooming or clumps. As a result, the rod's service life will be shortened or it may need to be scrapped.

Reconditioning

Regular maintenance Generally, the rod does not require repair. However, deformation of the head causes high stresses on the entire contact surface between the rod and the breaker. It is recommended to repair it by milling or turning. Welding or flame cutting is not recommended as the heat generated may cause structural changes in the material and accelerate wear.

Chisel Model we can supply

| Excavator Chisel | |||||||

| Material:42crmo | |||||||

| Model | Dia | Lengt | Weight | Model | Dia | Lengt | Weight |

| SOOSAN | FURUKAWA | ||||||

| SB43 | 75 | 740 | 23 | HB100 | 55 | 500 | 9 |

| SB50 | 100 | 1050 | 58 | HB200 | 70 | 510 | 13 |

| SB60 | 120 | 1050 | 91 | HB700 | 104 | 940 | 49 |

| SB70 | 135 | 1200 | 117 | HB1G | 36 | 400 | 3 |

| SB80 | 140 | 1200 | 130 | HB2G | 45 | 460 | 4 |

| SB120 | 155 | 1450 | 193 | HB3G | 60 | 560 | 11 |

| SB121 | 155 | 1450 | 193 | HB5G | 75 | 650 | 20 |

| SB130 | 165 | 1500 | 227 | HB10G | 105 | 1000 | 65 |

| SB130-3 | 155 | 1500 | 185 | HB15G | 120 | 1000 | 80 |

| SB150 | 175 | 1600 | 272 | HB30G | 150 | 1300 | |

| SB160 | 175 | 1600 | 272 | F-1 | 36 | 400 | 3 |

| SH200 | 70 | 600 | 16 | F-2 | 45 | 480 | 5 |

| SH400 | 95 | 840 | 40 | F-3 | 52 | 520 | 8 |

| SH700 | 105 | 930 | 55 | F-4 | 60 | 540 | 11 |

| SH18G | 120 | 1110 | 85 | F-5 | 68 | 610 | 16 |

| SH20G | 135 | 1200 | 120 | F-6 | 75 | 720 | 23 |

| SH30G | 150 | 1300 | 157 | F-9 | 90 | 800 | 32 |

| SH35G | 140 | 1300 | 137 | F-12 | 105 | 1000 | 66 |

| SH40G | 160 | 1400 | 192 | F-19 | 120 | 1100 | 86 |

| SH50G | 180 | 1515 | 263 | F-22 | 135 | 1200 | 117 |

| SB30 | 53 | 580 | 9 | F-35 | 150 | 1400 | 169 |

| KRUPP | INDECO | ||||||

| HM130/131/135/140V | 65 | 780 | 18 | MES180/181/200 | 48 | 550 | 6 |

| HM300/301/305 | 80 | 900 | 30 | MES300/301/350/351 | 55 | 600 | 10 |

| HM170/185/190V | 75 | 800 | 25 | MES451/521/550/HB5 | 65 | 650 | 14 |

| HM550/560CS/V | 100 | 1000 | 55 | MES601/621/650 | 80 | 650 | 22 |

| HM700/720CS/V | 115 | 1080 | 82 | MES1200-HB12 | 90 | 800 | 34 |

| HM900/901/902 | 135 | 1150 | 115 | MES1500/HB19 | 110 | 900 | 55 |

| HM950/960/SC/V | 135 | 1080 | 110 | MES1750/1800 | 114 | 1000 | 72 |

| HM1300/1500CS/V | 150 | 1200 | 151 | MES121/150 | 45 | 480 | 5 |

| HM1800/2000CS/V | 160 | 1400 | 220 | MES2000/HB27 | 120 | 1000 | 78 |

| HM2200/2500CS/V | 180 | MES2500 | 130 | 1100 | 101 | ||

| HM45 | 42 | 470 | 6 | MES3000 | 140 | 1200 | 130 |

| HM50/55 | 45 | 480 | 7 | MES3500 | 145 | 1300 | 155 |

| HM60/75 | 55 | 590 | 10 | MES4000 | 150 | 1300 | 160 |

| HM85/90 | 62 | 600 | 11 | MES5000 | 160 | 1350 | 190 |

| HM100/101 | 65 | 700 | 18 | MKB | |||

| HM200 | 80 | 785 | 27 | MKB1300N | 135 | 1150 | 116 |

| HM400/401 | 80 | 800 | 27 | MKB1400 | 135 | 1150 | 116 |

| HM600/601 | 100 | 1000 | 55 | MKB2000 | 150 | 1250 | 156 |

| HM800 | 135 | 1150 | 115 | MKB2000N | 149 | 1250 | 154 |

| HM1200 | 120 | 1250 | 155 | MKB2500 | 160 | 1350 | 185 |

| GUANGLIN | MKB3000 | 165 | 1500 | 227 | |||

| SG1800 | 135 | 1200 | 120 | MKB4000N | 180 | ||

| SG2100 | 138 | 1250 | 125 | MKB100 | 45 | 450 | 5 |

| Model | Dia | Lengt | Weight | Model | Dia | Lengt | Weight |

| GUANGLIN | MKB | ||||||

| SG2500 | 145 | 1300 | 151 | MKB150 | 55 | 600 | 10 |

| SG2800 | 155 | 1450 | 190 | MKB200 | 65 | 600 | 14 |

| SG3200/3300 | 158 | 1500 | 200 | MKB300N | 70 | 750 | 20 |

| SG5000 | 180 | 1600 | 280 | MKB400 | 80 | 600 | 21 |

| SG200 | 45 | 500 | 5 | MKB500 | 80 | 600 | 21 |

| SG300 | 57 | 600 | 10 | MKB800 | 100 | 1000 | 55 |

| SG350 | 68 | 700 | 17 | MKB900N | 100 | 1000 | 55 |

| SG400 | 75 | 690 | 20 | MKB1200 | 115 | 1150 | 84 |

| MONTABERT | DAENO | ||||||

| BRH75/76/90/91 | 60 | 550 | 8 | DMB03 | 68 | 600 | 16 |

| BRP85/100 | 62 | 620 | 12 | DMB04 | 95 | 900 | 43 |

| BRP130/150 | 75 | 740 | 21 | DMB06 | 105 | 930 | 55 |

| BRV32 | 122 | 1100 | 90 | DMB4000 | 150 | 1450 | 181 |

| BRV43 | 150 | 1300 | 160 | DMB5000 | 165 | 1600 | 249 |

| BRV45 | 150 | 1300 | 160 | S150 | 57 | 600 | 10 |

| BRV52 | 162 | 1350 | 192 | S500 | 69 | 680 | 18 |

| BRV53 | 170 | 1400 | 230 | S900 | 85 | 830 | 33 |

| BRV55 | 170 | 1500 | 245 | S1300 | 105 | 926 | 56 |

| BRV1600 | 140 | S1800 | 120 | 1000 | 80 | ||

| BRH40 | 45 | 500 | 6 | S2200-1 | 130 | 1200 | 112 |

| BRH125 | 80 | 700 | 21 | S2000-2 | 135 | 1200 | 121 |

| BRH250/270 | 95 | 850 | 40 | S2500 | 140 | 1200 | 130 |

| BRH501/570 | 114 | 1000 | 76 | S3000/3600/4500 | 150 | 1350 | 168 |