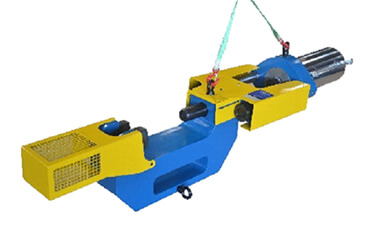

Portable Hydraulic track link pin press machine Track Link Pin Pusher for excavator and bulldozer

INTRODUCTION

Track Link Pin Pusher /Installer is specially designed for tracked machines, tractors,loaders, shovels, excavators, etc. It is suitable to use with JCB, Caterpiller, Komatsu and Poclain make track machines. It is safe and simple to use. Hydraulic force ensures smooth operation, thereby avoiding damage to the components of the track assembly.

Ideal for removal and installation of:

track pins,master pins,bushings,master bushings Easy to use equipped with a tripod stand to assist with positioning during operation in the field.

FEATURES

1.Portable for in field repair .

2.Double acting hydraulic cylinder for one-stroke removal or installation.

3.Tooling sets for pin sizes adjustments.

4.Storage case to house all components.

5.Cast steel frame construction for extended durability.

6.Eliminate dangerous removal methods.

7.Avoid machine component damage.

8.Reduced labour hours.

|

MODEL SPECIFICATIONS |

|||||||

|

Models |

Capacity (ton) |

Stroke (mm) |

Supported Pin Diameter (mm) |

Effective Area (cm2) |

Oil Capacity (cc) |

Assembly Length (mm) |

Weight w/Stand (kg)* |

| GT-50 |

50 |

250 |

19.3 - 36.4 |

70.88 |

1,772 |

1,400 |

85 |

| GT-100 |

100 |

350 |

19.3 - 60.2 |

132.7 |

4,645 |

1,750 |

205 |

| GT-150 |

150 |

350 |

23.7 - 70.0 |

213.8 |

7,484 |

2,103 |

372 |

| GT-200 |

200 |

350 |

36.4 - 73.9 |

283.5 |

9,923 |

2,245 |

630 |

OPERATING INSTRUCTIONS:

Ensure that oil is filled up to level in the hand pump oil tank. Connect hosepipes to hydraulic cylinder and hand pump. Operate directional valve handle for forward stroke and start operating pump handle, complete the forward stroke. Now operate directional valve handle to return stroke, complete the stroke. This results in removal of air entrapped inside the system.

Based on the tracked machine model select appropriate size of forcing pin and aligning bushes. Fit them inside the `C’ frame bore. Fit aligning adapter on `U’ cut out of the frame position the frame on the track of which the master pin is to be removed. Operate pump handle till master pin pusher touches the master pin. Once again visually ensure correct alignment and then operate pump handle to push master pin out. Retract ram fully and remove master pin pusher from front end. Now the track can be separated.

Ensure, Aligning bushes are within ‘C frame bore, during master pin removal. For fitment of master pin, master pin pusher should be fitted in the link assembly and master pin to be pushed in with the help of forcing pin after proper alignment.

Application

GT 50T

SAFE removal and installation of Track pins, Master pins, Bushings and Master bushings. Our presses include:

Covering Pin Size:

- Minimum Diameter: 19.3 mm

- Maximum Diameter: 36.4 mm

- Minimum Length: 133 mm

- Maximum Length: 178 mm

GT 100T

SAFE removal and installation of Track pins, Master pins, Bushings and Master bushings. Our presses include:

Covering Pin Size:

- Minimum Diameter: 19.3 mm

- Maximum Diameter: 60.2 mm

- Minimum Length: 160 mm

- Maximum Length: 320 mm

GT 150T

SAFE removal and installation of Track pins, Master pins, Bushings and Master bushings. Our presses include:

Covering Pin Size:

- Minimum Diameter: 22 mm

- Maximum Diameter: 70 mm

- Minimum Length: 311 mm

- Maximum Length: 365 mm

GT 200T

SAFE removal and installation of Track pins, Master pins, Bushings and Master bushings. Our presses include:

Covering Pin Size:

- Minimum Diameter: 36.4 mm

- Maximum Diameter: 73.9 mm, up to 90 mm available on request.