Rubber Track Conversion System for Tractors and Combines

Conversion Track System

Rubber Track Solutions is your headquarters for dependable full undercarriage systems for agriculture equipment. Find GT Conversion Track Systems (CTS) for combines and tractors. The GT conversion track system increases your machine’s mobility and flotation for better access to fields with soft ground conditions. Its large footprint reduces ground compaction, minimizes field damage, and increases stability, maximizing the overall efficiency and quality of your work. Flexible and adaptable like no other, it can be used on different machine models.

| Model | CBL36AR3 |

| Dimensions | wide 2655*high 1690(mm) |

| Track Width | 915 (mm) |

| Weight | 2245 Kg (one side) |

| Contact Area | 1.8 ㎡ (one side) |

| Applicable Vehicles | |

| John Deere | S660 / S680 / S760 / S780 / 9670STS |

| Case IH | 6088 / 6130 / 6140 / 7130 / 7140 |

| Claas | Tucano 470 |

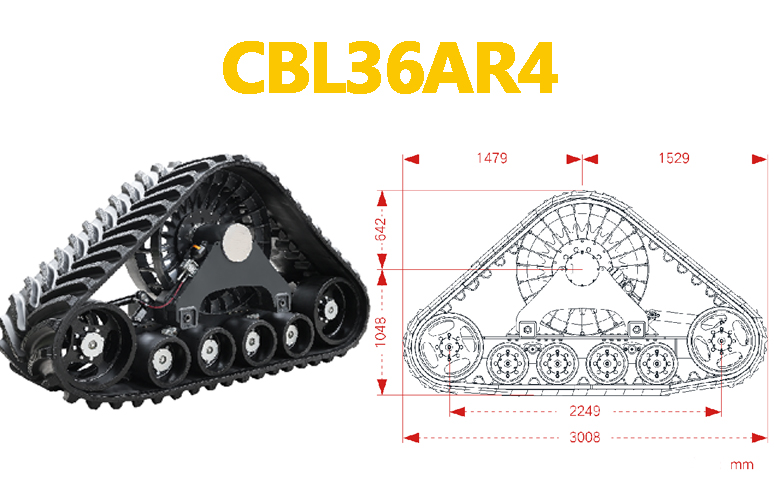

| Model | CBL36AR4 |

| Dimensions | wide 3008*high 1690(mm) |

| Track Width | 915(mm) |

| Weight | 2505 Kg (one side) |

| Contact Area | 2.1 ㎡ (one side) |

| Applicable Vehicles | |

| John Deere | S660 / S680 / S760 / S780 |

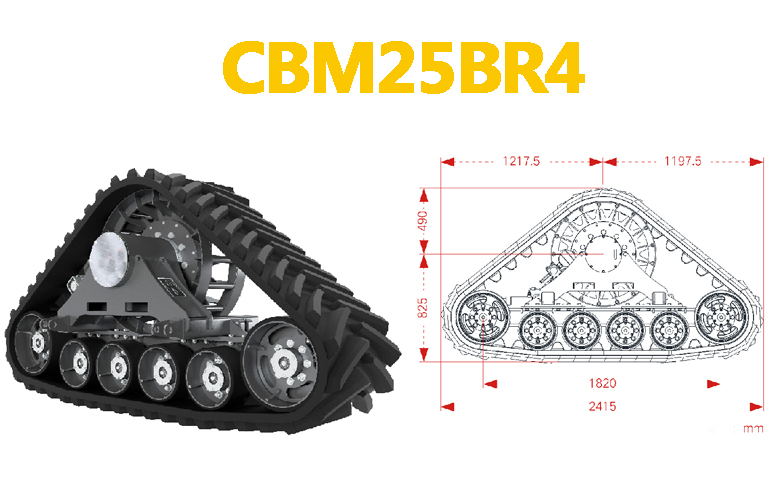

| Model | CBM25BR4 |

| Dimensions | wide 2415*high 1315(mm) |

| Track Width | 635 (mm) |

| Weight | 1411 Kg (one side) |

| Contact Area | 1.2 ㎡(one side) |

| Applicable Vehicles | |

| John Deere | R230 / 1076 |

| Case IH | 4088 / 4099 |

| LOVOL | GK120 |

Conversion Track System Details

Conversion Track System Application

What are the maintenance requirements for rubber track conversion systems?

Rubber track conversion systems for tractors and combines require regular maintenance to ensure optimal performance and longevity. Some common maintenance requirements for these systems include:

Regular cleaning to remove dirt, debris, and mud that can cause wear and tear on the tracks.

Inspection of track tension to ensure proper alignment and prevent premature wear.

Lubrication of moving parts to reduce friction and extend the life of the tracks.

Periodic track replacement when signs of wear or damage are present.

Checking for loose bolts or damaged components that may affect the overall performance of the system. Regular maintenance will help maximize the efficiency and lifespan of rubber track conversion systems for tractors and combines.