Hydraulic shears Car Dismantling Shears Hydraulic Power Shears

Hydraulic Power Shears

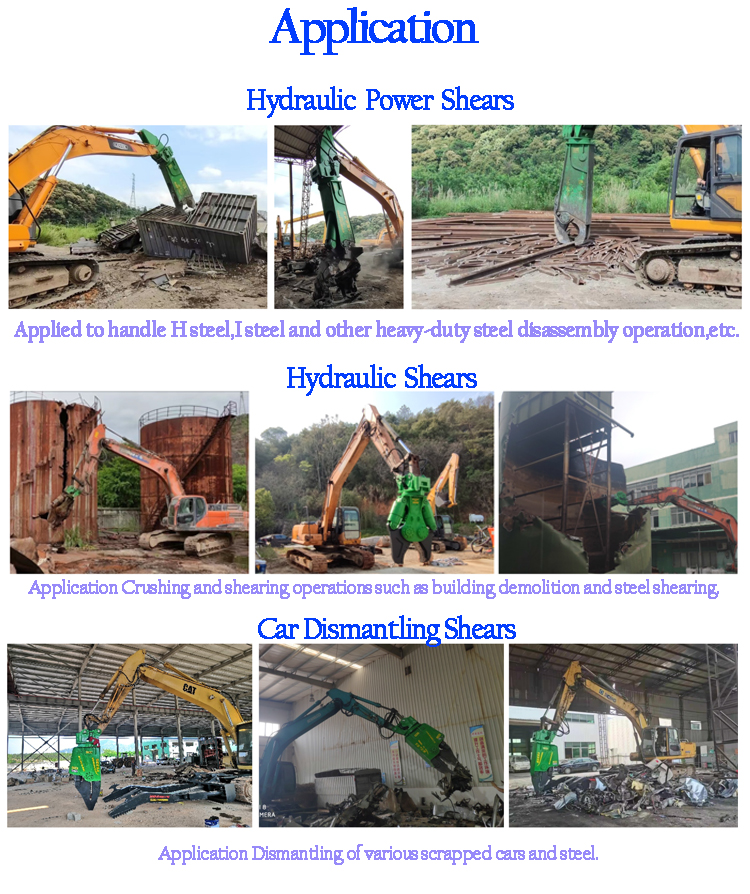

Application Applied to handle H steel,I steel and other heavy-duty steel disassembly operation,etc.

Features

Use Swedish Hardox 500, good toughness and wear resistance.

The pins use 42CrMo alloy steel, built-in oil passage,high strength and good toughness.

Adopt imported rotary motor, large torque and fast speed.

Big hydraulic cylinder adopts honing pipe and imported NOK oil seal, with short working period, long lifetime and powerful.

The cutter is made of ware-resistant alloy steel, which is resistant to high temperature and deformation.

| Item / Model | Unit | GT230 | GT330 | GT430 |

| Arm Installation | ton | 20-29 | 30-38 | 40-50 |

| Boom Installation | ton | 15-18 | 20-28 | 30-40 |

| Working Pressure | bar | 250-300 | 320-350 | 320-350 |

| Working Flow | L/min | 180-220 | 250-300 | 275-375 |

| Weight | kg | 2500 | 4500 | 5800 |

| Rotating Flow | L/min | 30-40 | 30-40 | 30-40 |

| Rotating Pressure | bar | 100-115 | 100-115 | 100-115 |

| Opening | mm | 500 | 700 | 730 |

| Cutting Depth | mm | 530 | 730 | 760 |

| Full Length | mm | 2700 | 3700 | 4000 |

Car Dismantling Shears

Application:Dismantling of various scrapped cars and steel.

Features:

1.Use Swedish Hardox 500,light weight and wear-resistant.

2.The pins use 42CrMo alloy steel, built-in oil passage,high strength and good toughness. Adopt Swiss imported rotary motor.

3.Big hydraulic cylinder adopts honing pipe and imported NOK oil seal, with short working period, long lifetime.

4.The cutter is made of ware-resistant alloy steel, which is resistant to high temperature and deformation.

| Item/Model | Unit | GT200 | GT225 | GT300 |

| Suitable Excavator | ton | 15-18 | 20-27 | 27-33 |

| Weight | kg | 1600 | 2000 | 2500 |

| Opening With Jaw | mm | 540 | 680 | 850 |

| Overall Length | mm | 2000 | 2600 | 2900 |

| Blade Length | mm | 240x2 | 240x4 | 240x4 |

| Max Cutting Force | ton | 208 | 259 | 354 |

| Driving Pressure | kgf/cm² | 320 | 320 | 320 |

| Driving Flow | L/min | 180-230 | 200-250 | 250-300 |

| Motor Set Up Pressure | kgf/cm² | 160 | 160 | 160 |

| Motor Flux | L/min | 36-40 | 36-40 | 36-40 |

| Frequency | r/min | 16-18 | 16-18 | 16-18 |

1.All are used mported materials, enough rigid , light and beautiful. The whole shear is not easy to deformation,no breaking knife, service life is more than 5 years.

2.The front pulling teeth adopt the whole high precision CNC machining center milling to maintain the high strength and wear resistance of imported materials. Large cylinder diameter, shear force that are easy to shear medium car chassis, and beam thick steel.

3.long time use will not make wrong knife,.The valve plug imported from the United States (Sun brand ) is stable in performance, long service life. Fast shearing speed, small car disassembly 6 minutes/machine, large car disassembly 10 minutes/machine.

Hydraulic shears

Application

Crushing and shearing operations such as building demolition and steel shearing;

Features

Use swedish Hardox 500+light weight and wear-resistant .

The pins use 42CrMo alloy steel,built-in oil passage,high strength and good toughness.

Adopt imported rotary motor,which rotates at all angles;

Big hydraulic cylinder adopts honing pipe and imported No K oil seal,with short working period,long lifetime .

The cutter is made of ware-resistant alloy steel,which is resistant to high temperature and deformation.

| Item | Unit | GT10 | GT20 | GT40 | GT80 | GT180V | GT280V | GT380V | |

| Suitable Excavator | ton | 0.8-1.5 | 1.5-3.0 | 4-9 | 6-10 | 12-18 | 20-30 | 26-305 | |

| Weight | kg | 135 | 210 | 400 | 600 | 1700 | 2950 | 3800 | |

| Opening | mm | 290 | 350 | 440 | 390 | 650 | 850 | 900 | |

| Blade Length | mm | 100 | 100 | 120 | 100 | 150 | 180 | 180 | |

| Height | mm | 1000 | 1055 | 1330 | 1280 | 1890 | 2010 | 2120 | |

| Width | mm | 660 | 690 | 770 | 850 | 1285 | 1350 | 1500 | |

| Crushing Force | ton | 20 | 22.5 | 50 | 20 | 80 | 100 | 120 | |

| Cutting Force | ton | 22 | 26 | 55 | 50 | 165 | 210 | 260 | |

| Driving Pressure | bar | 180 | 210 | 260 | 250 | 300 | 300 | 300 | |

| Driving Flow | L/min | . | . | . | 180 | 230 | 240 | 240 | |

|

Cycle TimeOpen |

Open | sec | . | . | . | 2.1 | 2.9 | 2.9 | 2.9 |

| Close | sec | . | . | . | 2.7 | 2.7 | 2.7 | 2.7 | |

Appliaction