Excavator Loader Bobcat Bucket Steel Bushings

The flange bucket bushing is a cylindrical mechanical part sleeved on the rotating shaft.. Generally speaking, interference fit is used for bush and bearing seat, and clearance fit is used for shaft.

The bushing is a component that fixes and reduces the friction coefficient of load in the process of mechanical transmission. The bushing is a whole structure, and there is a relative motion between the bushing and the pin when rotated.Essentially speaking,the bushing is acctually a kind of sliding bearing.

Oiling Grooves Type and its Characteristics

Bucket bushing we can supply

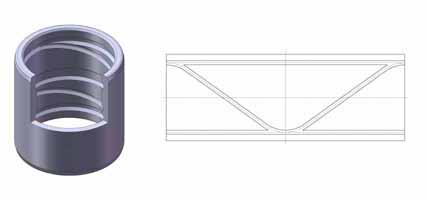

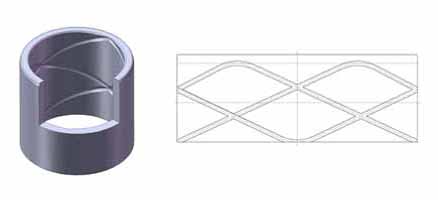

Spiral grooves,big pitch of screw is made on the internal surface to reserve and distribute lubricating oil,easy to manufacture and apply to axial movement mechanism.

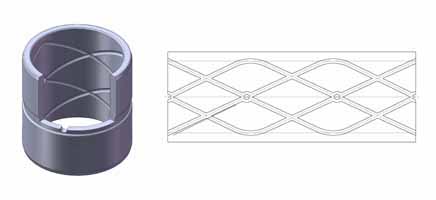

8-shape oiling grooves,has been sued for loader and some excavator for long tine,and has good oilong effects.

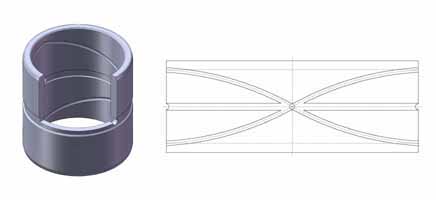

Cross-shape oiling grooves,its oil reserving ability and using effects is better than 8-shape oiling grooves, now it is largely used on excavator industry.

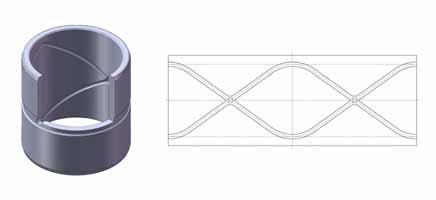

Dual-circle oilong grooves,original creation of our company,its oil reserving ability and using effects and loading area is two times as 8-shape oiling grooves.

Trip-circle oiling grooves,original creation of our company,its oil reserving ability and using effects and loading area is better than four cross-shape oiling grooves'.lt fulfills the heavy duty machine' requirements.

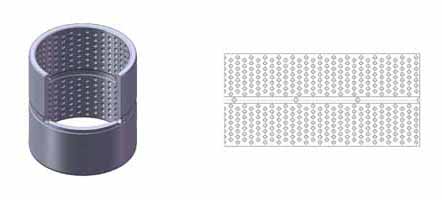

Oiling pits,its advantage is:

1. Oil reserve ability 3-5 times as other type oiling grooves and last long time with without maintenance.

2. The bearing's loading ability has almost not reduced with the oiling pits,so the bearing's using life is improved.

3. Every row oiling pits naturally forms wedge-shape oling angle to fast oil contact surface(See oiling wedge-shape sketch).

4. It can oil all the contact surface with a little turning action.

| No. | Spec.(mm) | N.W.(Kg) | No. | Spec.(mm) | N.W.(Kg) | |||||

| 1 | 45 | 55 | 45 | 0.28 | 51 | 75 | 90 | 90 | 1.37 | |

| 2 | 45 | 55 | 50 | 0.31 | 52 | 80 | 90 | 80 | 0.84 | |

| 3 | 45 | 60 | 50 | 0.49 | 53 | 80 | 90 | 90 | 0.94 | |

| 4 | 45 | 60 | 60 | 0.58 | 54 | 80 | 95 | 70 | 1.13 | |

| 5 | 40 | 50 | 45 | 0.25 | 55 | 80 | 95 | 80 | 1.29 | |

| 6 | 40 | 50 | 50 | 0.28 | 56 | 80 | 95 | 90 | 1.46 | |

| 7 | 50 | 50 | 50 | 0.34 | 57 | 80 | 96 | 90 | 1.56 | |

| 8 | 50 | 60 | 60 | 0.41 | 58 | 80 | 95 | 100 | 1.62 | |

| 9 | 50 | 65 | 50 | 0.53 | 59 | 80 | 96 | 100 | 1.74 | |

| 10 | 50 | 65 | 60 | 0.64 | 60 | 80 | 100 | 80 | 1.77 | |

| 11 | 50 | 70 | 60 | 0.89 | 61 | 80 | 100 | 85 | 1.89 | |

| 12 | 50 | 70 | 70 | 1.04 | 62 | 80 | 100 | 90 | 2.00 | |

| 13 | 55 | 65 | 50 | 0.37 | 63 | 80 | 105 | 90 | 2.57 | |

| 14 | 55 | 65 | 60 | 0.44 | 64 | 80 | 105 | 100 | 2.85 | |

| 15 | 55 | 70 | 50 | 0.58 | 65 | 80 | 110 | 70 | 2.46 | |

| 16 | 55 | 70 | 60 | 0.69 | 66 | 80 | 110 | 80 | 2.81 | |

| 17 | 55 | 70 | 70 | 0.81 | 67 | 80 | 110 | 90 | 3.16 | |

| 18 | 55 | 75 | 70 | 1.12 | 68 | 80 | 120 | 90 | 4.44 | |

| 19 | 55 | 80 | 70 | 1.46 | 69 | 85 | 100 | 80 | 1.37 | |

| 20 | 60 | 70 | 60 | 0.48 | 70 | 85 | 100 | 90 | 1.54 | |

| 21 | 60 | 70 | 70 | 0.56 | 71 | 90 | 105 | 70 | 1.26 | |

| 22 | 60 | 75 | 60 | 0.75 | 72 | 90 | 105 | 80 | 1.44 | |

| 23 | 60 | 75 | 70 | 0.87 | 73 | 90 | 105 | 90 | 1.62 | |

| 24 | 60 | 75 | 80 | 1.00 | 74 | 90 | 106 | 90 | 1.74 | |

| 25 | 60 | 75 | 90 | 1.12 | 75 | 90 | 105 | 100 | 1.80 | |

| 26 | 60 | 80 | 50 | 0.86 | 76 | 90 | 106 | 100 | 1.93 | |

| 27 | 60 | 80 | 60 | 1.04 | 77 | 90 | 105 | 110 | 1.98 | |

| 28 | 60 | 80 | 70 | 1.21 | 78 | 90 | 110 | 80 | 1.97 | |

| 29 | 60 | 80 | 80 | 1.38 | 79 | 90 | 110 | 90 | 2.22 | |

| 30 | 65 | 80 | 60 | 0.80 | 80 | 90 | 110 | 100 | 2.46 | |

| 31 | 65 | 80 | 65 | 0.87 | 81 | 90 | 115 | 80 | 2.53 | |

| 32 | 65 | 80 | 70 | 0.94 | 82 | 90 | 115 | 90 | 2.84 | |

| 33 | 65 | 80 | 80 | 1.07 | 83 | 90 | 120 | 80 | 3.11 | |

| 34 | 65 | 85 | 60 | 1.11 | 84 | 90 | 120 | 90 | 3.49 | |

| 35 | 65 | 85 | 70 | 1.29 | 85 | 90 | 125 | 90 | 4.17 | |

| 36 37 |

65 | 85 | 80 | 1.48 | 86 | 90 | 125 | 100 | 4.64 | |

| 37 | 70 | 80 | 80 | 0.74 | 87 | 90 | 125 | 110 | 5.10 | |

| 38 | 70 | 80 | 90 | 0.83 | 88 | 90 | 130 | 90 | 4.88 | |

| 39 | 70 | 85 | 70 | 1.00 | 89 | 90 | 130 | 100 | 5.42 | |

| 40 | 70 | 85 | 75 | 1.07 | 90 | 100 | 115 | 90 | 1.79 | |

| 41 | 70 | 85 | 80 | 1.15 | 91 | 100 | 116 | 90 | 1.92 | |

| 42 | 70 | 85 | 90 | 1.29 | 92 | 100 | 115 | 100 | 1.99 | |

| 43 | 70 | 90 | 80 | 1.38 | 93 | 100 | 116 | 100 | 2.13 | |

| 44 | 70 | 90 | 80 | 1.58 | 94 | 100 | 115 | 110 | 2.19 | |

| 45 | 70 | 90 | 90 | 1.77 | 95 | 100 | 120 | 90 | 2.44 | |

| 46 | 71 | 86 | 60 | 0.87 | 96 | 100 | 120 | 100 | 2.71 | |

| 47 | 71 | 86 | 70 | 1.02 | 97 | 100 | 120 | 110 | 2.98 | |

| 48 | 71 | 86 | 80 | 1.16 | 98 | 100 | 130 | 100 | 4.25 | |

| 49 | 75 | 90 | 70 | 1.04 | 99 | 100 | 130 | 110 | 4.68 | |

| 50 | 75 | 90 | 80 | 1.22 | 100 | 100 | 130 | 120 | 5.10 | |