China Bulldozer Track Link for Komatsu Caterpillar

Descripción

What are the two types of track chain?

There are two types of track chains that exist for heavy machinery: dry chains and lubricated chains. As the name implies, the differences lie in the amount of lubrication on the track's pins and bushings, which can impact cost and the amount of wear a track receives over time.

What are the different types of track chain?

Chains may be divided into the following types: sealed, sealed and greased, sealed and lubricated (also referred to as self-lubricating).

Types of Track Chains – Dry Chains vs. Lubricated Chains

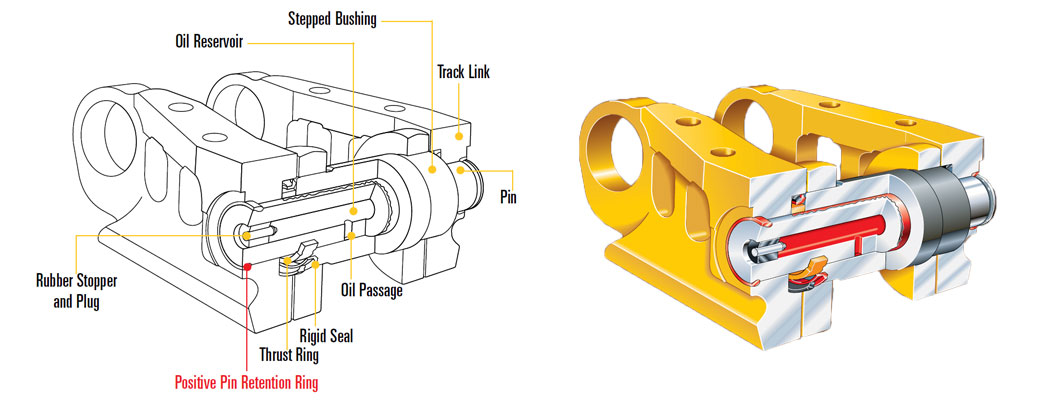

Lubricated chains are track chains that have lubricants permanently sealed into the space between the pin and the bushing. These seals are built to provide lasting lubrication and reduce the amount of wear that occurs due to friction on the pins and bushings. Unlike with dry chains, lubrication is automatic. However, lubricated chains usually cost more than dry chains in the short term.

On the other hand, dry chains can be manufactured with grease between the pin and bushings, but the seals on these chains are generally less durable and may leak relatively quickly. Some dry chains may come sealed, but they may not be lubricated. With most dry chains, you will have to routinely lubricate your pins and bushings in order to avoid wear, as lubrication is not automatic. While dry chains are less expensive than lubricated chains, they will experience a significant amount of wear without sealed lubrication and will likely cost you a good deal of money in replacement parts over time.

Analyze component

| The track link has been done special hardening treatment which ensures its high strength and excellent abrasion resistance&inductive harden surface | The bushing shaft has been carburized and quenched the surface with medium frequency,which guarantees its reasonable hardness of core and abrasion resistance of the inner and outer surfaces. | The pin shaft is quenched the surface with medium frequency after quenching and tempering,which ensures its sufficient core strength and wear-resistance of inner and outer surfaces. | Lubricated track link assemblies subassemblies,such as oil seals,are made from world well-known brands.high-quality oil seals guarantee the maximum longevity of lubricated track link assemblies. |

Model We Can Supply

| Model | Lubricated Stype | Dry Stype | Weight |

| D31 | Lubricated Stype 43L | Dry Stype 43L | |

| D50 | Lubricated Stype 39L | Dry Stype 39L | |

| D65 | Lubricated Stype 39L | Dry Stype 39L | 650kg |

| D65EX-12 | Lubricated Stype 39L | Dry Stype 39L | 650kg |

| D85 | Lubricated Stype 38L | Dry Stype 38L | 750kg |

| D155 | Lubricated Stype 41L | Dry Stype 41L | 1100kg |

| D275 | Lubricated Stype 39L | 1516kg | |

| D3C | Lubricated Stype 43L | Dry Stype 43L | |

| D4D | Lubricated Stype 36L | Dry Stype 36L | |

| D6D | Lubricated Stype 39L | Dry Stype 39L | 650kg |

| D6H | Lubricated Stype 36L | Dry Stype 39L | 650kg |

| D7G | Lubricated Stype 38L | Dry Stype 38L | 750kg |

| D8N | Lubricated Stype 44L | Dry Stype 44L | 1180kg |

| D8L | Lubricated Stype 45L | 1200kg | |

| D9N | Lubricated Stype 43L | 1560kg | |

| D10 | Lubricated Stype 44L | 2021kg | |

| D11N |

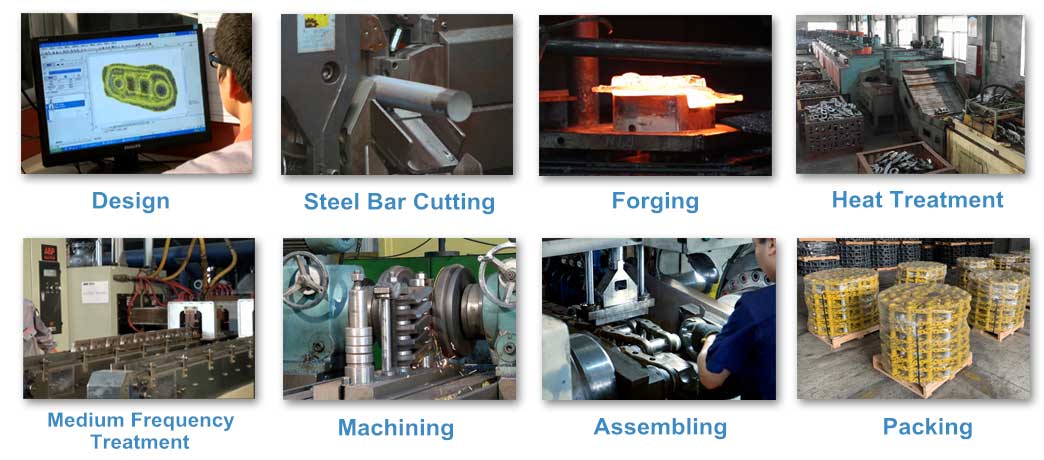

Track Chain Production Line