Big Discount Caterpillar Track Pin Press - High efficiency Portable Line Boring And Welding Machine for Construction Machinery Maintenance – Globe Truth

Big Discount Caterpillar Track Pin Press - High efficiency Portable Line Boring And Welding Machine for Construction Machinery Maintenance – Globe Truth Detail:

220v 480vconstruction machinery repair boring machine 2.5kw stepless speed regulation multi-function CNC type welding machine

Our company’s CNC portable soldering and welding machine is designed for on-site construction. It is characterized by small size, light weight, good boring and welding quality. It is not required for use environment and space, and is easy to carry. It is widely used in the repair of round holes such as pin holes and bearing holes of large-scale equipment and engineering machinery. It is a good helper for industrial and mining enterprises and engineering site maintenance.

1. Adopt digital control system, precise control and simple operation

2. It can realize common boring, fixed length boring, spiral welding, swing welding and other functions.

3. Fixed length stop function, truly unattended

Boring machine Specification

Main motor power: 1.5kw, stepless speed change (0-180 RPM).

Feed box: stepless speed regulation, automatic feed.

Cutter motor: 220V, 120W stepless speed regulation

Boring range: diameter 45mm-200mm.

Boring bar specification: 40mm * 1500mm (can be customized according to customer requirements)

Boring bar material: 45 × 3.

Boring bar processing technology: tempering, turning, quenching, grinding, hard chromium plating on the surface.

Feed guide rail: double cylinder guide rail (45 × steel, tempering, turning, quenching, grinding, hard chromium plating).

Cutting feed: minimum 0.10 mm / revolution.

Maximum cutting amount: 2 mm for one side.

Working schedule: 300 mm (can be customized according to customer requirements).

Weight: About 60kg.

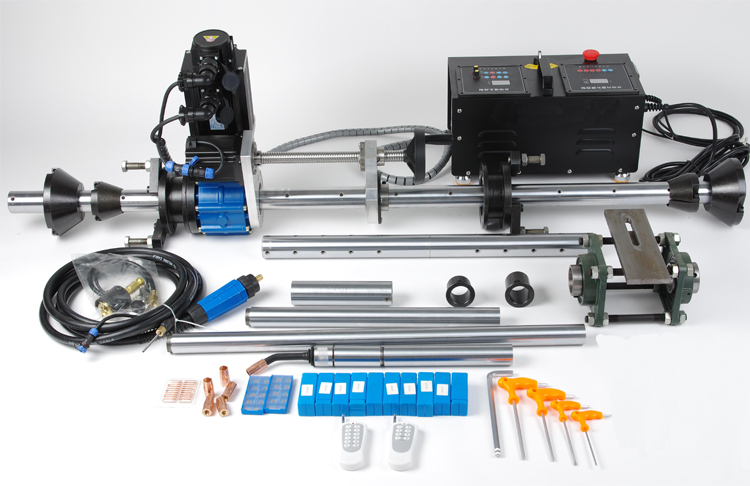

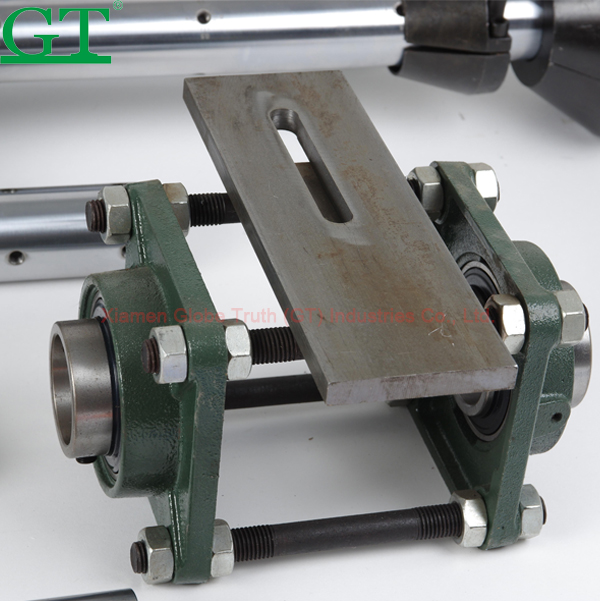

Boring machine part

Our Service

Pre-sale Service

1.Supply item design,process design.

2.Help you to chose the fit machine.

3.Making the machine according to your requirement.

Sale Service

1.Acceptance equipment together with you.

2.Help you to make the method statement and the details of the process.

After Service

1.Guarantee for a year.

2.Quality problem,we will send you the accessories.

3.Free repair whole using life(without the freight and accessories charge).

Hole and Boring machine Operation

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Big Discount Caterpillar Track Pin Press - High efficiency Portable Line Boring And Welding Machine for Construction Machinery Maintenance – Globe Truth, The product will supply to all over the world, such as: Mauritania, Mexico, Pakistan, With high quality, reasonable price, on-time delivery and customized & customized services to help customers achieve their goals successfully, our company has got praise in both domestic and foreign markets. Buyers are welcome to contact us.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.