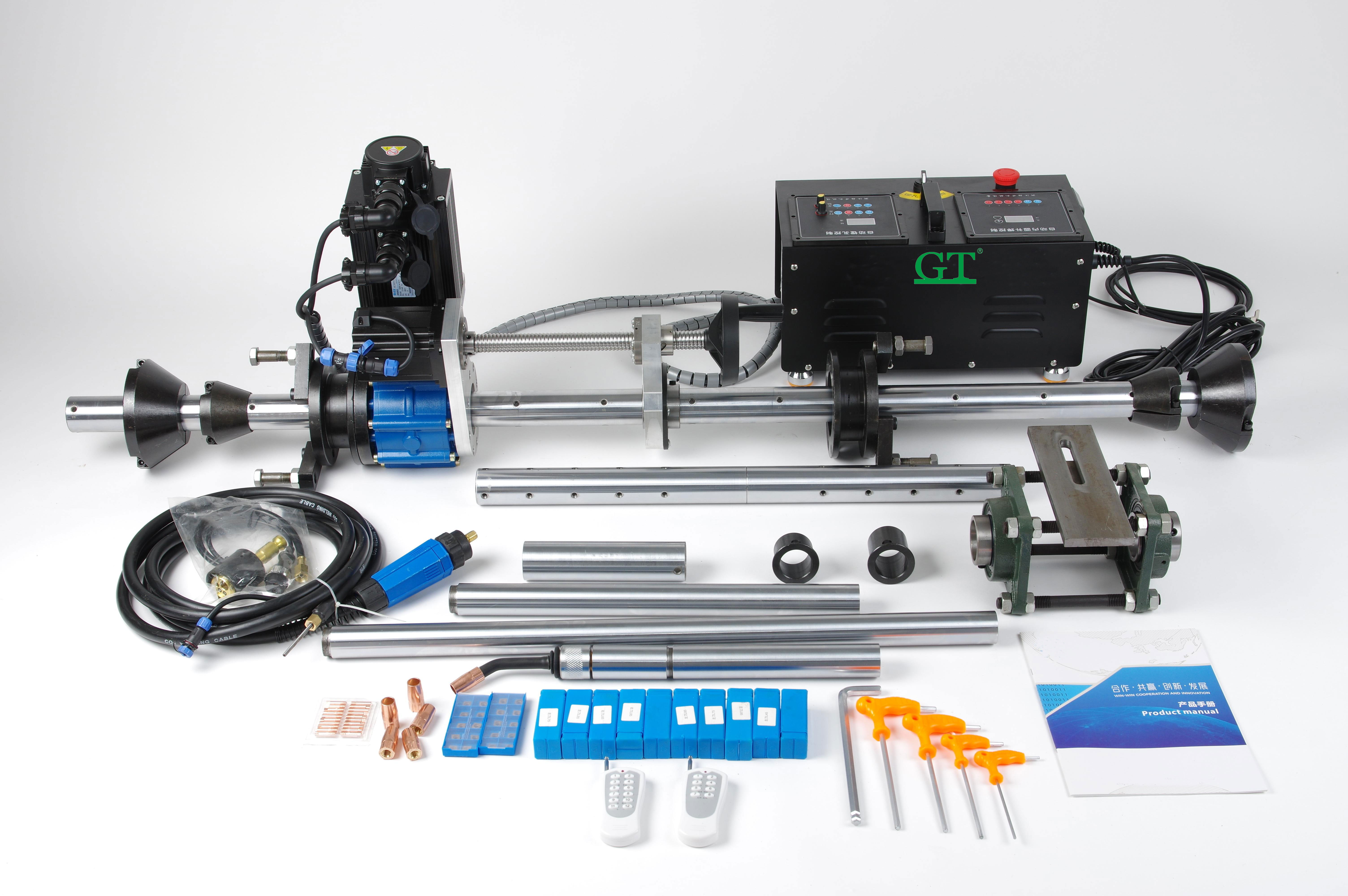

Our 2 in 1 Portable line boring and welding machine is mainly used for processing different kinds of concentric interval bore and side-by-side porous with continuous cutting or do the bushing after re-boring, it is in high efficiency and accuracy.

For the welding part, it can be widely used to weld and repair the hole of large-sized machinery, pivot pin hole of earth moving equipment and bearing hole. It is ideal and necessary equipment for the industry and mining enterprise and on-site engineering repairing.

The machine not only can do the repairing and machining of the concentric hole of excavator, crane and truck crane etc., but also can bore the pivot pin bore, rotary hole and the articulated hole after welding.

The machine adopts the way of welding and bolt fixing on the holder, it is convenient and safe for installation & dismounting

| Parameter | Description |

| Function | Boring and weilding for construction machine |

| Main motor power | Servo motor3000W |

| Voltage | 220/ 380V/ 50/60HZ |

| The speed of Boring bar’s turn | 50-300 minute |

| Vf : Adjustable speed | continuously variable |

| Welding Hole diameter | 40-300mm |

| Roundness of machining hole | ≤0.02mm |

| Operate way | Boring and welding together |

| Executive standard | QYS0579-2018 |

| The Spindle motor power | 400W |

| Stroke | 300mm (we can according demand made 1 meter) |

| The Processing range of the aperture diameter | 40-160 |

| Unilateral cutting volume | 8mm |

| Welding Hole diameter | Ra3.2 |

Post time: Nov-16-2021