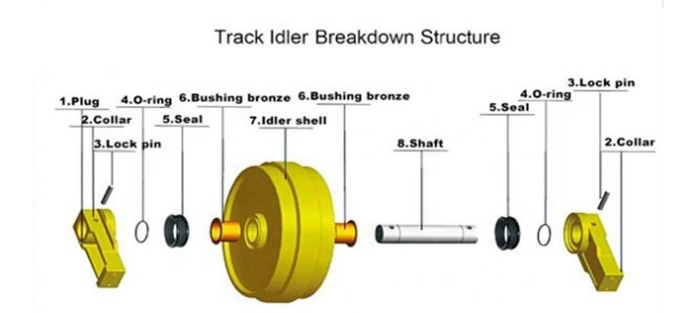

The front idler is a critical component in the undercarriage system of tracked heavy equipment such as excavators, bulldozers, and crawler loaders. Positioned at the front end of the track assembly, the idler guides the track and maintains the appropriate tension, playing a pivotal role in both performance and longevity of the entire undercarriage system.

Primary Functions of Front Idlers

1.Track Tensioning:

The front idler works in conjunction with the recoil spring and tensioning mechanism to apply consistent tension to the track chain. This prevents excessive sagging or overtightening, which could otherwise lead to premature wear of track links and rollers.

2.Track Alignment:

It serves as a guide to keep the track in proper alignment during operation. A well-functioning idler reduces the risk of de-tracking, especially under heavy side loads or on uneven terrain.

3.Load Distribution:

Although it does not carry as much vertical load as the rollers, the front idler assists in distributing the dynamic forces across the undercarriage. This minimizes localized wear and contributes to smoother machine operation.

4.Vibration Damping:

Through its movement and recoil mechanism, the idler helps absorb shocks and vibrations transmitted from ground contact, protecting both the track and chassis components.

Common Wear Issues

1.Flange Wear: Continuous friction from side travel or misalignment can cause the idler flanges to wear out, leading to poor track guidance.

2.Surface Pitting or Spalling: High impact forces or poor lubrication may result in surface fatigue.

3.Seal Failure: Seal degradation can lead to lubricant leakage, exposing the bearing to contaminants and accelerating wear.

Maintenance Best Practices

1.Regular Inspection:

Visual checks for cracking, flange wear, and oil leaks should be part of routine maintenance. Check for unusual track slack, as it may indicate recoil spring failure or idler misalignment.

2.Track Tension Adjustment:

Ensure the track tension falls within the manufacturer’s specification. Both under-tension and over-tension can cause idler misalignment and damage the recoil mechanism.

3.Greasing and Lubrication:

Many idlers are sealed-for-life, but if applicable, maintain proper lubrication levels to protect internal bearings.

4.Undercarriage Cleaning:

Remove compacted mud, debris, or frozen material around the idler to avoid increased friction and uneven wear.

5.Replacement Timing:

Monitor wear patterns and replace idlers when wear limits are reached, typically measured against OEM specs. Ignoring worn idlers can lead to accelerated damage to track links, rollers, and the recoil spring.

Conclusion

The front idler, though often overlooked, is fundamental to track stability, tension, and undercarriage efficiency. Timely maintenance and inspections can significantly reduce downtime, extend the service life of the undercarriage, and improve machine productivity.

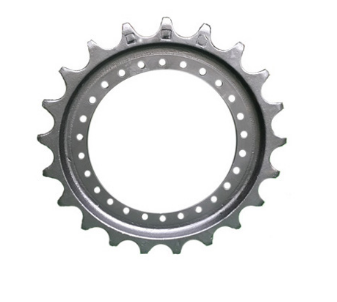

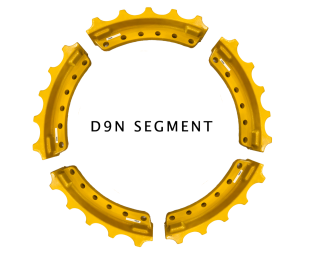

Sprockets and Segments: Structure, Selection, and Usage Guide.

Sprockets and segments are critical drive components in the undercarriage system of tracked heavy equipment, including excavators, bulldozers, and mining machinery. They engage with the track chain bushings to transfer torque from the final drive to the track, enabling forward or reverse movement.

Sprocket

Segment

Structure and Materials

Sprockets are typically a one-piece casting or forging with multiple teeth, while segmented sprockets (segments) are modular, bolted directly onto the drive hub. This segmented design allows easier replacement without disassembling the final drive.

High-wear resistance is essential. Most sprockets are made of high-strength alloy steel and undergo deep induction hardening to achieve surface hardness of HRC 50–58, ensuring extended wear life in abrasive environments.

Selection Guidelines

Match Pitch and Profile: The sprocket must match the pitch and bushing profile of the track chain (e.g., 171mm, 190mm). Incorrect pairing will cause accelerated wear or de-tracking.

Machine Compatibility: Always refer to OEM specs or part numbers to ensure proper fit with your specific equipment model (e.g., CAT D6, Komatsu PC300).

Teeth Count and Bolt Pattern: Teeth count and mounting hole patterns must align precisely with the final drive hub to avoid installation issues or gear misalignment.

Usage Tips

Monitor Bushing Engagement: Excessive track wear or elongation can cause sprockets to skip, leading to tooth damage.

Replace as a Set: It's recommended to replace sprockets along with the track chain to maintain synchronized wear.

Inspect Regularly: Cracks, broken teeth, or uneven wear patterns indicate it’s time for replacement.Proper selection and maintenance of sprockets and segments directly impact undercarriage efficiency, reducing downtime and operating costs.

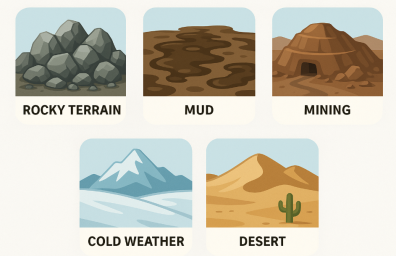

How to Choose the Right Undercarriage Parts for Different Working Environments?

Selecting the correct undercarriage parts is critical to equipment performance and durability. Different working environments place varying demands on components such as track chains, rollers, idlers, and sprockets.

Rocky Terrain:

Choose heavy-duty rollers and sealed track chains with high wear resistance. Forged sprockets and induction-hardened segments offer better impact resistance.

Muddy or Wet Conditions:

Use self-cleaning track shoes and track links with wider grousers. Double-flanged rollers help prevent derailment in unstable ground.

Mining or High-Abrasion Zones:

Opt for reinforced idlers, high-hardness bushings, and thicker track links. Chromium-molybdenum alloy steel components perform well under abrasive wear.

Cold Weather:

Select components with low-temperature resistant seals and greases. Avoid brittle materials that may crack in sub-zero conditions.

Sand or Desert:

Use closed-type rollers to prevent sand ingress. Minimize friction through surface treatment and proper lubrication.

Always follow OEM specifications, and consider aftermarket upgrades tailored to your jobsite. The right parts reduce downtime and maximize service life.

Why Heavy-Duty Sprockets and Rollers Are Crucial for Rocky Terrain?

Rocky terrain presents one of the most demanding environments for tracked construction machinery. Sharp, abrasive rocks generate extreme impact and friction, causing accelerated wear on undercarriage parts—especially sprockets and track rollers.

Heavy-duty sprockets, made from high-strength alloy steel and induction-hardened to HRC 50–58, are designed to resist cracking, chipping, and deformation. Their deeper tooth profile provides better engagement with track bushings, reducing slippage and improving torque transfer under heavy loads.

Track rollers in rocky terrain must withstand constant pounding and side loading. Double-flanged, forged rollers with thick shells and heat-treated shafts are essential for stability, track guidance, and long service life.

Without reinforced sprockets and rollers, frequent part failure can occur—leading to increased downtime, maintenance costs, and even safety risks. Heavy-duty components ensure sustained performance, especially in mining, quarrying, and mountainous operations.

Broken SPROCKET

Broken TRACK ROLELR

Post time: Aug-04-2025